Description

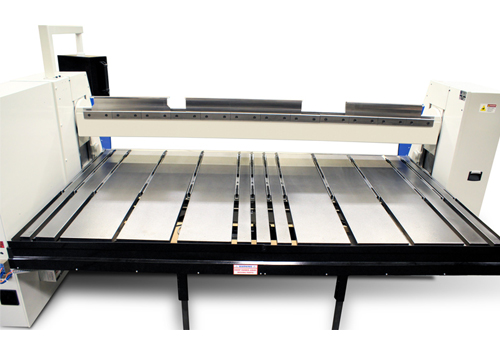

Roper Whitney Kombi Autobrake Series AB1014

For over 20 years, Roper Whitney has been producing quality folding systems for a variety of markets. Building on that experience, the Generation “2” Autobrake integrates advanced design with the features that have made the Autobrake the choice of professionals.

The Autobrake combines automated bending of angles up to 145°, material clamping, and material support into a single CNC controlled system employing wing bending techniques.

Manufacturing, service, and applications support are based in Rockford, IL U.S.A.

Benefits of the Generation “2” Autobrake system vs. manual or press brake bending are:

Reduced labor costs

Improved part accuracy

Reduced setup time

Minimized tool changes

Improved part quality especially on soft and pre-painted material

The Generation “2” Autobrake is a plate and weldment steel construction, delivering superior performance and features in a simplified rigid design. End housings are a plate-type construction bringing drive components close together for improved stiffness and performance. Actuating mechanisms are secured in rigid mounts at the outside of the housings, allowing easy maintenance.

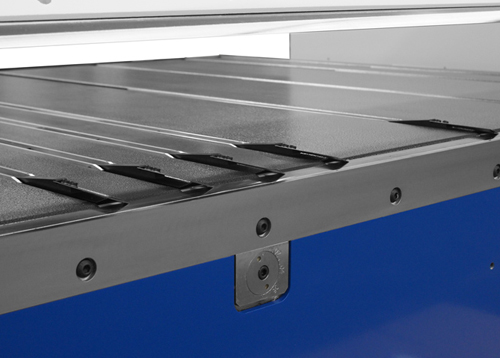

The unique Kombi beam is a fabricated structural prism on which is mounted tooling to firmly clamp a broad range of materials, close hems, and withstand the forces generated by capacity forming operations. Machined into the Kombi beam 180° from each other are the attachment surfaces for the straight and box and pan tooling. Tools are attached to the Kombi beam with standard socket head cap screws. Grooves are provided to secure tools even while the clamping bars are loosened for adjustment. Rotation of the Kombi beam is powered by a brake motor driving a sprocket and roller chain mechanism.

Clamping and hemming are programmed. The upper beam is driven to program settings on both ends by a brake motor and eccentric drive of the beam with a connecting shaft. Clamping and hemming power is delivered to the clamp jaws by a series of spring washers to provide variable clamping pressures with a shock-absorbing end stop. This provides reliable clamping pressure regardless of material thickness. Integral to the upper beam are the ways with non-metallic gibing to guide and retain the upper beam within the end housings.

Part program operation and creation are accomplished on a pendant-mounted computer control, located at the right-hand side of the machine. Programs are presented in a logical organized manner similar to the steps used to create parts on traditional folding brakes, allowing an easy rapid transition to the Autobrake. The computer control can be rotated into position for best use, and can be positioned to the rear of the machine.

Programming Functions are:

Bend Angle

Gauging distance

Spring back compensation

Offsets for hem operations

Radius profile macro gauge

Programmable delay for back

Customer alpha/numeric part number

Open hem height

Open, closed, or teardrop hemming entering of part

Information screen for related data

Material handling instructions

Jaw opening

Programmable part counter