Description

The ROPER WHITNEY Long Folder Series (LFS), gives you added flexibility with the ability to handle lengths as great as 40’. Best of all, it includes technology so advanced and easy-to-use that a novice worker could be accurately creating complex shapes in minutes.

Coupled with a highly robust SLITTER the Roper Whitney Long Folder means you can quickly produce pieces of long folded metal up to 9 gauge. Capable of as many as 100 folds per program, the Roper Whitney Long Folder is ideal for builders, metal part fabricators, roofing companies and others who create complex profiles and need the flexibility and throughput of a long folding system.

The Roper Whitney Long Folder employs a highly reliable hydraulic motor system for the folding beam. Because of this, it delivers the speed and precision you need, making the system fast and accurate. For example, the 90-degree fold speed is just 5 seconds (adjustable to customer needs).

• Energy-saving hydraulics

• Maximum fold angle of 145 degrees

• International standard laser finger detection and other safety devices

• Auto radius function

• Built in slitter (to further reduce width)

Built for your longest metal folding needs, Roper Whitney Long Folders are also backed by one of the longest, strongest warranties in the metal folding industry. They are backed by our highly responsive service network and durably built to serve you for many years to come. Simplified electronic circuitry and easily accessible components further simplify maintenance.

SIMPLICITY, INTELLIGENCE, EASE-OF-OPERATION

Simple and familiar Windows®-based software environment delivers impressive control and networking capability.

Other features include:

• Remote diagnostics

• Off-line programming capability

• Virtually infinite library storage

• Automatic bend sequence calculation and animation

*Note that the long folders are available from 21’ to 40’ and bending capacities up to 9 gauge.

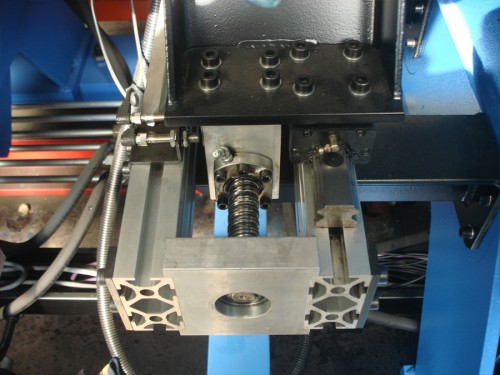

There are two different and distinct models to choose from depending on your application. The first style is the new model BZ. This new model has a host of new features that make it very appealing in the roofing and metal building industry. The first thing that you will notice is the amount of free space located around the nose bar and folding beam areas. The nose bar is designed in a way that allows for very generous return flanges that allows the operator to design parts that could not normally be done on a folding machine in the past. The folding beam is also recessed at 25 degrees to allow more free space especially when making drip edge for higher pitched roof lines. Also on this new model there is an integrated crowning feature that allows individual adjustment of each C-frame.

This new model comes in standard lengths of 13’, 21’ and 26’ feet in length and comes with a standard 49” backgauge dimension. BZ can be ordered in 18, 16 and 14 gauge mild steel capacity versions.